DK Automatics offers products, systems and solutions to specific industries like, Packaging, Textiles, Material Handling, Electronics, Tyre, SPM and Machine Retrofits. Our aim is to deliver high precision, efficiency and reliability to Discrete Industry customers.

As consumerism grows, attractive and quality packaging is a key driver influencing product purchase. Hence, Packaging is viewed as a critical industry serving multiple industries – B2C or B2B. Typically, packaging involves labour-intensive tasks, some need human intelligence and others may be simple repetitive tasks.

DK Automatics’ high-speed, high-response, high-accuracy Servo System, provides an excellent synchronized follow-through function that responds rapidly and has accurate correction capability for achieving positioning precision and increased productivity. In addition, DK Automatics’ high resolution AC Servo Motors provide smooth operations, which do not require acceleration or deceleration and lead to noise reduction. Further, it optimises damage to mechanical structures and maintenance costs.

In most sectors of textile manufacturing process, automation is key to quality improvement and cost competitiveness. Early modernization and technical developments in textiles concentrated on the automation of textile machines and their processes. Now automation has taken place in all the processes involving textile manufacturing – Cotton picking, ginning, spinning, weaving, and processing and even to some extent in garment making, resulting in enormous gains in productivity and efficiency. Automation has made in-roads in:

• Fiber Manufacturing

• Yarn Manufacturing/Spinning

• Weaving/Fabric Manufacturing

• Dyeing and Printing

• Textile Finishing

DK Automatics offers a full set of cotton spinning equipment control programs that mainly focus on low power consumption, high speed, automation and digitization. By using a PLC as the main controller, an encoder for positioning detection, AC Motor Drives or AC Servo Drives for motion control, the textile requirements of high-speed and high-precision tension control and synchronization control can be effectively addressed. The parameters can also be set by an HMI to regulate temperature control and production process detection, which can be effectively used in mercerizing, bleaching, dyeing, washing, jig dyeing and calico printing machines.

Heavy lifting and technology reflect the country’s might in developmental pursuit. Material handling is thus the prime mover in diverse industries such as Realty, Retail, Mining, Construction, Ports, Logistics & Warehousing, Oil & Gas and Manufacturing. DK Automatics solutions aim to improve safety, reliability and accuracy in control, operation and maintenance of a host of material handling equipment and systems.

Electronics industry operates in a highly dynamic and competitive environment. In addition, working with micro components and harnessing need speed and precision. DK Automatics provides a wide range of fast and high precision automation products to meet market needs including AC motor drives, AC servo drives and motors, programmable logic controllers, optical vision systems, human machine interfaces, temperature controllers and pressure sensors. These products are integrated into various solutions to perform precise high-speed control tasks including shifting, detection, pick and place, and many more.

Retrofitting and Re-manufacturing high value or special purpose machine tools where replacement is not financially feasible or the machine has a large work envelope with quality and substantial machine components. A retrofit can be as basic as replacing old axes motors and drives with new AC digital servo technology. A comprehensive retrofit for example would include an all new machine electrical system such as CNC control, AC digital servo motors and drives, complete machine wiring, linear and rotary encoders for closed loop positioning feedback, new operator pendent, and new electrical cabinet.

For a comprehensive retrofit, DK Automatics will provide a complete documentation package including electrical schematics, fault lists, and troubleshooting guidelines. Machine operation Training and Manufacturer’s Warranty are also provided.

DK Automatics has requisite know-how and expertise to provide innovative special purpose solutions for all industries, across the entire machine building process (Mechanical, Electrical, Control & instrumentation and Assembly). Our competency in building such specialised solutions and developing new technologies makes us your ideal partner to custom-craft machine for unique needs:

• Assembly machines

• Testing machines

• Marking Machines

• Leak Test Machines

• Pick & Place Devices

• Feeding Mechanisms

• Bottle Cleaning Machines

• Artificial Intelligence

The rubber and tyre industry is a highly volatile and competitive market. Hence, effective mixing of raw materials with right composition is key to product quality. DK Automatics solution adopts a holistic approach – from raw materials process and mixing, to component preparation, to tyre production and curing, through to final finish and inspection. In addition, support safety, material handling, and energy management. Using state-of-the-art processor architectures in combination with the high-speed PLC system provides the performance required to map all automation functions on one centralised system encompassing safety, measurement, condition monitoring and robotics. In addition to sequential control tasks, Motion Control, and HMI.

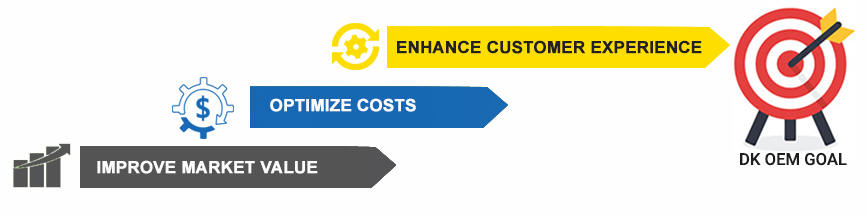

As a machine manufacturer who enables the production and delivery of a variety of goods, you are constantly challenged by market dynamics. Be it resource constraints or economic changes or consumer preferences or environmental mandates, your business needs to be agile and responsive to overcome the churn and stay profitable.

Automation gap in OEMs is defined by the business model of their operations:

No matter, which stage of the business cycle you are operating, DK Automatics can help you transition into a competitive agile manufacturing entity. We provide an end-to-end service right from design, build, integration to O & M through best-fit technology, materials and people.

DK Automatics offers remote, onsite technical training and support, which ensures your business is always ahead and capable to overcome any business or technical challenge.